Customers Increasingly Expect Your Company to Make a Difference

Doing good doesn’t have to hurt the bottom line.

Customers Increasingly Expect Your Company to Make a Difference

Illustrations by Muti

Companies such as Dell and BMW use an assemble-to-order production strategy that keeps common components on the factory floor, ready for final assembly into the type of personal computer or vehicle that a customer orders. This is great for companies looking to satisfy a large volume of demand but that don’t want to build whole units in advance, to avoid any unsold products. However, the difficulty of estimating how much of each component to hold in stock and how to allocate components to each product can keep companies from maximizing ATO’s benefits in practice, according to Chicago Booth’s Levi DeValve and Duke’s Saša Pekeč and Yehua Wei.

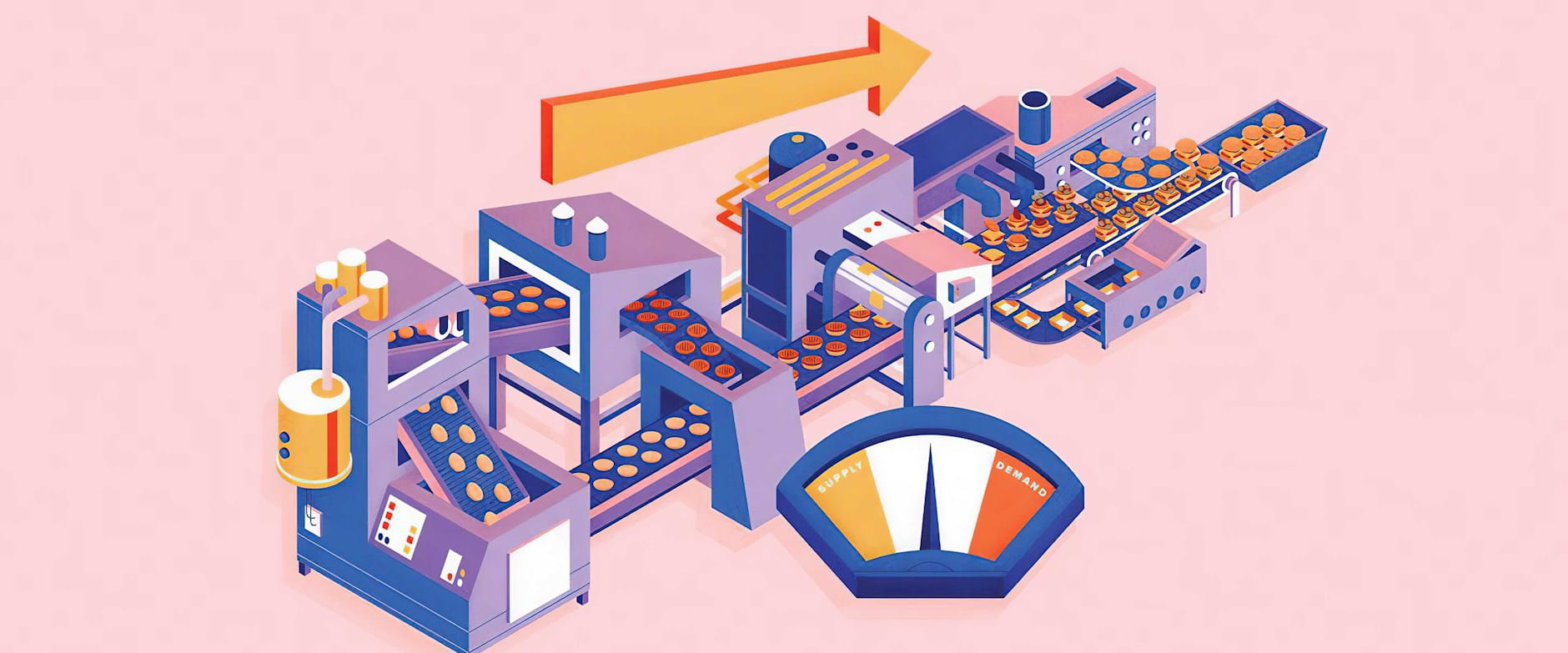

Make-to-stock strategy: MTS managers forecast consumer demand and match anticipated orders with an inventory of fully assembled products.

Make-to-order strategy: On the other hand, MTO systems wait for a customer’s order to arrive before starting production. Because this can include procuring parts and assembling components, MTO often results in a longer lead time.

Assemble-to-order strategy: An ATO strategy aims to combine the best of both systems—its flexibility lets companies fulfill large orders relatively quickly with minimal unsold inventory, yet still allows customers to partially customize orders. Here is how it works:

Managers must decide the quantity of components to order even before they can ascertain customer demand for their products.

When customers’ orders arrive, managers must then choose how to allocate the supply of components to each product for assembly.

The aim is to minimize not only inventory costs from ordering too many components but also product shortages that result in a failure to fulfill customer demand for all products. Shortage costs can include not just revenue lost from canceled orders but also goodwill lost from customers who agreed to wait.

Managers of large-scale operations have an especially difficult time computing the optimal solution due to the many decisions they have to make in combination, according to DeValve, Pekeč, and Wei. To address this problem, the researchers designed a computationally efficient algorithm that can generate better decisions for:

• SUPPLY: How much to order of each component

• DEMAND: How to prioritize product assembly when orders arrive

An approach that can scale up: The researchers’ technique involves balancing inventory and shortage costs to come as close as possible to the optimal cost. Their algorithm, which takes a new approach to analyzing this problem, does not degrade in performance as the problem grows in size, a crucial stability guarantee for the scale of modern applications that has been lacking in the existing algorithms.

Closer to the optimal solution: In numerical simulations, the researchers find that their algorithm outperforms existing methods—on average, it comes within 1 percent of the optimal solution compared with 5 percent to 13 percent for other methods.

Besides classic assembly-line businesses such as carmakers and computer manufacturers, service and retail companies can also follow an ATO strategy. For example, food-service companies have to maintain an adequate supply of fresh ingredients. For retail giant Amazon, one of its important supply decisions is which products to stock in regional warehouses so it can fulfill as many items as possible in a single order.

Levi DeValve, Saša Pekeč, and Yehua Wei, “A Primal-Dual Approach to Analyzing ATO Systems,” Management Science, May 2020.

Doing good doesn’t have to hurt the bottom line.

Customers Increasingly Expect Your Company to Make a Difference

Doing what’s always worked will, at some point, no longer work. A willingness to experiment is key.

In Business, Don’t Leave Well Enough Alone

Research examines the role of the media in determining how much credence people give to expert advice.

Fox News Causes Viewers to Disregard Social DistancingYour Privacy

We want to demonstrate our commitment to your privacy. Please review Chicago Booth's privacy notice, which provides information explaining how and why we collect particular information when you visit our website.